Mangaflo™ is a manganese and iron removal treatment process of water for human consumption.

Overview

Iron and manganese, in high concentration make the water unfit for human and domestic consumption.

To meet new requirements, the basic process has evolved enabling total arsenic removal also. This new process is called Mangaflo™ Plus.

The Mangaflo™ process is used in:

- Groundwater treatment;

- Surface water treatment;

- Industrial process water treatment.

Features & Benefits

- No utilization of strong oxidant;

- 15 years of experience;

- Support durability;

- Durable manganese, iron and arsenic removal, depending on the process chosen;

- Adaptation to variations in concentration;

- No reagent under or over dosing;

- Sludge production minimized;

- Easy to operate.

Applications

Manganese removal is conventionally done by physical-chemical treatment. It involves chemical oxidation of manganese producing an insoluble manganese oxide. This oxidation is following by retention on granular material such as sand.

Unlike conventional treatment, which requires addition of a strong oxidant (potassium permanganate, chlorine or ozone) to obtain sufficient oxidation, the Mangaflo™ process developed by Veolia Water Technologies provides manganese treatment with an ecological aspect. Indeed, oxidant addition is no longer required because the process uses the manganese dioxide catalytic effect.

Water is filtered on a thick layer of manganese dioxide which acts as a catalyst and as an oxidant with the dissolved manganese in the water to be treated. So, the treated water complies with drinking water standards, with a residual manganese rate in the effluent lower than 5-20µg/l, depending on its design.

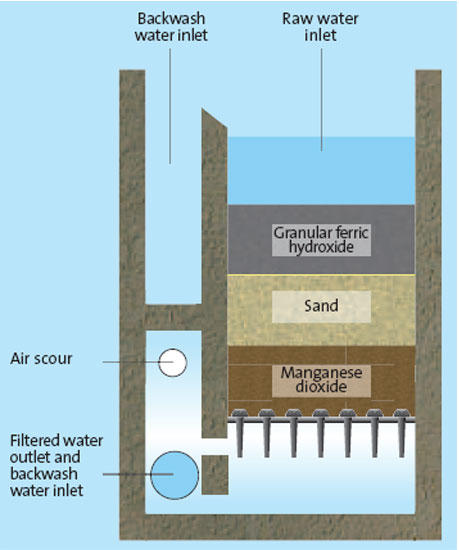

Mangaflo™ Plus is based on the same principle with an essential iron oxide layer added for arsenic removal. This materiel acts as an adsorbent. According to installation treatment capacity, filtration is carried out with an open or pressurized filter.

This process is composed of three filter media layers:

- An upper layer composed of iron hydroxide grain;

- An intermediate layer composed of sand and/or anthracite

- A lower layer composed of manganese dioxide.

Focus on manganese dioxide

Manganese dioxide is a ground and sieved natural material from the mining industry; there are several varieties, the most common is pyrolusite. One of the outstanding features of manganese dioxide is its high density. Manganese dioxide acts as a catalyst and also as an oxidant. Its mode of action is dual:

- 1.Catalytic action: the material serves as a support for dissolved manganese adsorption;

- 2.Oxidant action: the manganese dioxide serves as an oxidant for the dissolved manganese in the water to be treated.

The use of a fluidized bed allows Actina™ to run with high rising rates, around 80 to 100 m/h and confers it a small footprint.