Sustainable Water Management for Pharmaceutical Companies and the Cosmetic Industry

Veolia Water Technologies partners with pharmaceutical and cosmetic manufacturers across Australia and New Zealand to deliver sustainable water management solutions. We specialise in developing treatment solutions for pharmaceutical and cosmetic wastewater, water for injection (WFI), clean steam, and compendial water systems dedicated to helping you reduce production costs while protecting your valuable installations. With expertise in treating all types of wastewater, we also ensure the delivery of compendial water that complies with stringent pharmacopoeial requirements

Water and environment: challenges faced by pharma & cosmetic companies

Water Security Risks

High-quality water is critical for production, and secure, reliable water sources are essential.

Managing Water Usage

Our technologies help clients significantly reduce water consumption without compromising quality.

Environmental Impact

Our pharmaceutical and cosmetic wastewater treatment solutions control and minimise environmental impacts.

How Veolia is committed to helping its pharmaceutical and cosmetic clients

We have extensive experience in product development, project management and service offerings for water for pharmaceutical purposes.

By listening to our customers, we have developed a range of utility water, compendial water (including purified water, water for injection and clean steam) and wastewater treatment solutions for pharmaceutical and cosmetic purposes. These are critical for compliance with regulations and environmental targets, and to improve your manufacturing efficiency

- Production of purified water.

- Water for injection (WFI).

- Clean steam and management of wastewater.

- Development of water reuse and resource recovery.

Efficient wastewater treatment ensures regulatory compliance while creating opportunities for the recovery of valuable resources and a reduced water footprint through reuse strategies.

Global Support with Local Expertise

Veolia Water Technologies offers a global network of pharmaceutical service specialists, providing emergency support, preventative maintenance, and predictive maintenance programmes.

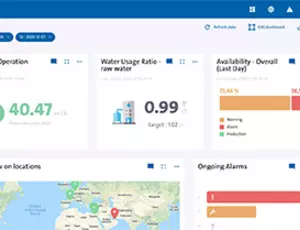

Our predictive maintenance aligns with Industry 4.0 principles, with Hubgrade technology allowing Veolia experts to remotely monitor and advise on plant operations, ensuring maximum uptime, compliance, and efficiency.

Wastewater treatment ensures compliance and may also offer opportunities to recover valuable elements and reduce the plant's water footprint through reuse.

Tailored Solutions for the Pharmaceutical and Cosmetic Industries

Process water

Our customised solutions for process water are designed to meet the specific requirements of our customers, producing high-quality water from diverse feed sources and significantly lowering water usage.

We deliver systems to produce clean steam and compendial water, supporting the most demanding pharmaceutical and cosmetic manufacturing processes.

- Compendial Water: Our technologies produce compendial water that meets international pharmacopeial standards, ensuring the highest quality for pharmaceutical manufacturing, including applications requiring sterile environments and strict regulatory compliance.

- Clean Steam: We supply clean steam systems that meet stringent sterility and purity requirements, crucial for sterilisation processes and critical production environments.

Wastewater treatment

Our pharmaceutical and cosmetic wastewater treatment technologies effectively remove dissolved and suspended contaminants, ensuring water discharged into the environment or reused within the plant meets strict regulatory standards. We also help businesses reduce waste disposal costs and meet sustainability goals.

Trusted by Leading Pharmaceutical and Cosmetic Brands

Veolia Water Technologies proudly partners with global and local leaders in the pharmaceutical and cosmetic sectors, helping them achieve water management excellence.

Veolia manages water, waste, energy and for Swiss pharmaceutical giant Novartis in 15 European sites

Our water technologies produce compendial waters, treat challenging effluents and implement circular savings by exploiting valuable by-products.

Discover Our Pharmaceutical Water Expertise

We offer comprehensive water solutions for both non-critical utilities and highly specialised pharmaceutical and cosmetic applications, where only the highest quality water will suffice.

All Veolia Water Technologies’ systems for compendial water production are fully compliant with GAMP, cGMP, ISPE, and FDA guidelines. They meet the stringent quality specifications of global pharmacopoeias, including the USP and Ph Eur, ensuring peace of mind and assured compliance for your operations, wherever you are based.

Our extensive technology portfolio for pharmaceutical and personal care product manufacturers also includes advanced wastewater treatment solutions for both pharmaceutical and cosmetic applications.

SEE ALL OUR TECHNOLOGIES

The European Pharmacopoeia changed the WFI (Water for Injection) monograph 0169 back in April 2017 to allow production of WFI water with a twin membrane process. The skid-mounted multi-technology Orion unit consisting of softening, reverse osmosis and EDI coupled up with a UF unit can provide cold WFI water.

This product mitigates the perceived risks of membrane systems with the ability to be frequently hot water sanitized above 80C including as an option the pretreatment. Coupled with suitable system monitoring including TOC, this provides a robust and reliable system complemented by a VWT Pharma service contract and presents a viable option to conventional distillation.

Ranj Rihal

Product & Marketing Solutions

Business Development Manager

Veolia Water Technologies

Contact Ranj through his LinkedIn account

Would you like more information about our technologies for the pharmaceutical & cosmetics industry?

More services for our healthcare and cosmetic clients

FAQ about water solutions for pharmacy and cosmetic

Do pharmaceutical water systems require special treatments?

Companies supplying water treatment equipment must ensure that their products are able to produce the quality of water required for the production application as specified by the applicable pharmacopeia., that the technologies employed are authorized for use under the applicable pharmacopeia and that the equipment is manufactured and may then be maintained in compliance with cGMP guidelines. The latter requires proof, which is supplied in the form of various "validation" documents.

What are the different applications for pure water within the pharmaceutical industry?

Within the pharmaceutical industry, water is most commonly used in liquid form, not only as an ingredient in many formulations but also as a cleaning agent. Production of Purified Water, Pyrogen Free Water (Cold WFI), Water for Injection (WFI) and Clean Steam to international pharmaceutical standards is widely recognised as a critical process.

What is purified water? How is purified water used in pharmaceutical applications?

Purified water not only has relatively high purity in ionic terms, but also low concentrations of organic compounds and micro-organisms. Water of this quality can be used for a multiplicity of applications, including makeup and rinse water for large and small volume parenterals, genetically engineered drugs, serum/media, ophthalmic solutions, antibiotics, vaccines, cosmetics, veterinary products, OTC and ethical products, fermentation, medical devices, nutraceuticals and diagnostics. Purified water can be produced by water purification systems incorporating reverse osmosis and ion exchange, second pass RO or CEDI, and often also with UV treatment.

What is pyrogen-free water? How is pyrogen-free water used in pharmaceutical applications?

Pyrogen-free water is required in applications such as mammalian cell culture. Ultrafiltration is used to remove any significant levels of biologically active species such as endotoxin (typically <0.25 IU/ml) and nucleases and proteases (not detectable). With the changes in the European Pharmacopoeia this can now be used for the production of cold WFI.

What is Water for Injection? How is Water for Injection used in pharmaceutical applications?

Water for Injection (WFI) is used as an excipient in the production of parenteral (medicines that are typically injected into the body) and other preparations where product endotoxin content must be controlled, and in other pharmaceutical applications, such as the cleaning of certain equipment and parenteral product components. WFI is mainly produced using distillation but double membrane based systems are also an option.

What is clean steam? How is clean steam used in pharmaceutical applications?

Clean steam, or pure steam as it is sometimes known, is used where the steam or its condensate would directly contact official articles or article-contact surfaces, such as during their preparation, sterilisation, or cleaning where no subsequent processing step is used to remove any impurity residues.