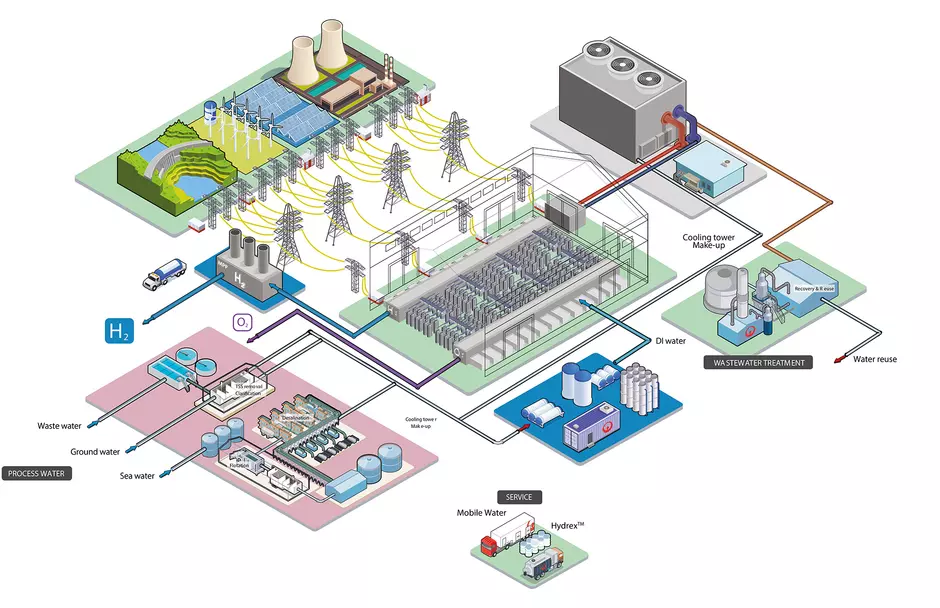

Hydrogen can be produced from a variety of sources — from natural gas to nuclear power and biogas —and green hydrogen is produced from renewable sources such as solar and wind. Regardless of the source, pure water is critical to hydrogen production and so managing water resources is vital from electrolysis efficiency to water treatment services for electrolysis.

Water and environment: challenges faced by hydrogen producers

Managing a range of water sources

Ensuring cost effectiveness

Minimizing downtime

Overcoming water security risks

How Veolia is committed to helping its hydrogen clients

Green hydrogen production can drive the global economy from its current fossil fuel-dependent structure to the renewable energy-driven, net zero approach of the future.

As a result, the electrolyzer market — the devices that enable the production of hydrogen using a chemical process that separates water into hydrogen and oxygen molecules — is gaining serious momentum. This is not only due to the increasing adoption of sustainable power but also the stringent regulatory policies that many countries are putting in place to reduce their emissions.

At Veolia Water Technologies, we are positioned to support both the green hydrogen — hydrogen produced from renewable sources — and blue hydrogen — hydrogen produced from natural gas and supported by carbon capture and storage — industries.

We focus on designing and packaging together world class water treatment technologies and services that improve hydrogen electrolysis efficiency. Our three offers include boxed, standard and bespoke solutions covering ranges from 100 kilowatt hour (kWh) to over 500 megawatts (MW).

Ensuring Ultra Pure Water Treatment for Efficient Hydrogen Production in Australia and New Zealand

Water plays a critical role in every stage of the water treatment for the hydrogen electrolysis process. One of the key challenges in the hydrogen water plant industry is ensuring a consistent and reliable supply of high-purity water to maintain efficient operations.

The Importance of Water Quality for Green Hydrogen Production

To facilitate electrolysis, pure water treatment is essential, particularly for polymer electrolyte membrane (PEM) electrolysers, which require water with ultra-low conductivity (typically less than 0.1 microsiemens per centimetre (μS/cm)). Maintaining this level of water quality for hydrogen production ensures optimal performance and longevity of the system.

Beyond process water, high-purity water is also required for utility feed applications such as cooling and water for steam production in large-scale hydrogen facilities.

Managing Wastewater and Water Scarcity in Hydrogen Electrolysis

In addition to ensuring high-purity feed water, hydrogen water plant operators must effectively manage wastewater. Residual streams from membrane filtration and sludge accumulation can present operational challenges. Water treatment for hydrogen electrolysis must, therefore include efficient wastewater treatment and disposal strategies.

With increasing concerns about water scarcity, especially in Australia and New Zealand, hydrogen production facilities must be capable of sourcing and treating various types of water, including groundwater, surface water, and even seawater. In regions with limited freshwater availability, treated wastewater can provide a sustainable alternative.

Advanced Pure Water Treatment Solutions for Hydrogen Electrolysis

Our expertise extends to treating diverse water sources, from groundwater and surface water to seawater desalination. To maximise water recovery, water reuse strategies and zero liquid discharge (ZLD) solutions can help reduce wastewater disposal costs. For offshore or coastal hydrogen projects, thermal desalination presents an energy-efficient and viable solution.

To address these water-related challenges, hydrogen water plant operators require a trusted partner who can manage the full water cycle. Our industry-leading solutions encompass reverse osmosis (RO) and continuous electro-deionisation (CEDI) technologies, ensuring consistent water quality for hydrogen production regardless of the source.

Scalable Water Treatment Solutions for Hydrogen Production

We offer tailored solutions for various hydrogen production scales:

- Small-scale hydrogen production (100-900 kWh): Packaged box solutions

- Medium-scale hydrogen production (20-100 MW): Two standard treatment packages

- Large-scale hydrogen production (500+ MW): Customised solutions for both onshore and offshore applications

Adaptable solutions for all hydrogen players

Hydrogen clients who already work with Veolia

Our client needed to expand their offer to provide water purification systems to its growing customer base as part of an overall package. Our experts designed and delivered a modular system to effectively treat feedwater to the required quality that then fed the proton exchange membrane (PEM) electrolyzers. It was tailored to manage inlet water with high hardness and salinity while also handling variable flow rates. The plant includes both softening and reverse osmosis to meet the electrolysers required conductivity of less than three micro siemens per centimetre.

Discover our water treatment technologies for the hydrogen industry

The shift to climate neutrality is both a pressing challenge and an opportunity to create a better future for all. Hydrogen, and especially green hydrogen, is a tool we can use to meet soaring energy demands while cutting our greenhouse gas emissions. We are here to help you find the best water solutions for your entire water cycle to aid the energy transition.

Dionisio Visintin

Commercial Excellence and Hydrogen Manager Europe

Contact Dionisio through his LinkedIn account

Would you like more information about our technologies to support Hydrogen production?

Ongoing Maintenance for Water Treatment in Hydrogen Electrolysis

As residuals naturally accumulate over time, continuous monitoring and maintenance are crucial to sustaining efficient water for hydrogen production. Our global service support ensures the complete water cycle remains optimised, reducing operational costs and energy consumption.

Frequently Asked Questions (FAQ)

How is Hydrogen fuel made?

Hydrogen is produced by splitting water for hydrogen production into hydrogen and oxygen through electrolysis. An electric current is passed through the water, separating the hydrogen for energy use while safely releasing oxygen into the atmosphere.

How does efficient water treatment for hydrogen electrolysis reduce costs?

Although water represents a small fraction of hydrogen production costs, optimising pure water treatment can enhance efficiency and reduce expenses by:

- Treating alternative water sources such as polluted or brackish water

- Recovering energy from excess heat

- Utilising oxygen as a secondary product

- Extending the lifespan of electrolytic cells through improved water quality for hydrogen production

- Minimising downtime due to maintenance-related disruptions

Can seawater be used for electrolysis?

Yes, any water source—including seawater, groundwater, or treated wastewater—can be used for electrolysis, provided it undergoes proper pure water treatment. For PEM electrolysers, water must be purified to below 1 μS/cm before it can be effectively used.

By implementing advanced water treatment for hydrogen electrolysis solutions, the hydrogen industry can secure a sustainable and cost-effective approach to hydrogen production.