As a global leader in water treatment and resource recovery, Veolia Water Technologies delivers customised mine water management solutions designed to meet the unique needs of the mining industry across Australia and New Zealand. Our specialised mine water treatment technologies effectively manage and treat water to reduce environmental impact, increase resource efficiency, and support sustainable operations.

Environment and regulations: challenges faced by the mining industry

A water-dependent sector.

Usually located in areas of water stress.

Strong environmental regulations.

How Veolia is committed to helping its mining clients

Veolia Water Technologies’ expertise guarantees the complete management of the entire water cycle – a vital component for the smooth operation of our customers’ businesses in the mining industry.

As a water treatment specialist, we provide a full range of water services for mining, including preliminary and detailed engineering, provision of standard and custom equipment, project management and maintenance services, as well as long-term operation or temporary mobile water solutions.

Our solutions are specifically customized to meet both environmental and economic objectives.

Our Mine Water Treatment Solutions & Capabilities

Using a range of innovative mine water treatment technologies, we are able to develop water treatment solutions for mining that are not only reliable and cost-effective but also meet the most demanding standards in terms of performance and efficiency. Whatever your specific requirements, we can create a water treatment process solution that meets them in full.

Desalination

Desalination is an increasingly key solution for scarcity of water, guaranteeing water supply even in periods or areas of drought. Combined with local presence and a worldwide network of experts, we ensure our clients the best possible solutions to supply high-quality water, manage brine concentrates, produce or recover energy, extract raw materials, and capitalize on by-products.

Process Water

Our process water solutions are designed to meet the customer’s needs, producing high-quality process water from a range of feed water sources and significantly reducing water consumption.

Wastewater Treatment

We are experienced in helping clients reduce their financial exposure and comply with discharge requirements and stringent environmental regulations regarding wastewater management. We understand the unique requirements of mining operations and our worldwide expertise in mine water issues allows us to offer specialized water treatment solutions that treat water and efficiently remove a wide range of contaminants such as heavy metals and minerals, arsenic, suspended solids, organics, iron, manganese, and specific ions that can impact the local environment.

Pre-water Treatment for Mines

Our adaptable water treatment plants can meet the diverse water quality needs of mining sites throughout Australia and New Zealand. Veolia provides water treatment technologies that address both immediate and long-term requirements, ensuring that operations in even the most remote areas run smoothly.

Pre-Water Treatment Systems: For process water in mining facilities, including groundwater, surface water, greywater, and seawater desalination.

- Technologies: Actiflo®, Hydrex™ chemicals, Hydrotech™ Discfilters, Sea Water Reverse Osmosis (SWRO)

- Projects: Angas Zinc Mine, SA; Ballarat Goldfields, VIC; Bendigo Mining, VIC

Leach liquor filtration

Utilising precoat filtration and vacuum deaeration technologies, our leach liquor filtration systems help remove impurities, enhancing the extraction process and minimising the use of costly reagents like cyanide and zinc.

- Technologies: Auto-Jet® pressure leaf filter, HPD® Evaporation and Crystallisation

- Projects: Bendigo Mining, VIC

Tailings pond

Our tailings solutions effectively manage overflow and support resource recovery, maximising the extraction of valuable materials from mine waste while still maintaining compliance.

- Technologies: Actiflo®, Hydrotech™ Discfilters, Multiflo™

- Projects: Ballarat Goldfields, VIC; Bendigo Mining, VIC

Acid mine drainage

Using DenseSludge™ and OPUS® technology, Veolia’s acid mine water treatment solutions reduce sludge volume and improve the cost-efficiency of mine water management.

- Technologies: Actiflo®, AMDRO™, HPD® Evaporation and Crystallisation

- Projects: Angas Zinc Mine, SA

Resource Recovery Systems for Solution Mining

We provide advanced water treatment systems for solution mining, including HPD® evaporation and crystallization technologies, maximising resource recovery and efficiency.

- Technologies: Ion exchange, mineral precipitation, sludge drying

- Projects: Energy Resources of Australia (ERA), Ballarat Goldfields, VIC

Strong partnerships worldwide

Veolia Water Technologies is the world leader in water treatment. Present in all major mining countries, we have built trusting relationships with our partners. We guarantee mine sites are able to comply with ecological regulations while ensuring they achieve their business objectives as well.

Our partners find competitive advantages through synergies made possible by water technologies. A fine and balanced analysis of the environmental impact and a circular economy logic are firmly etched into our sustainable development values.

In Chile, Veolia Water Technologies is a partner of Coldeco on the El Teniente site.

Our group processes 3 million cubic meters of water a year to recover more than 1,600 tons of copper. Our facilities recover concentrated solutions of copper for revaluation by electrolytic extraction.

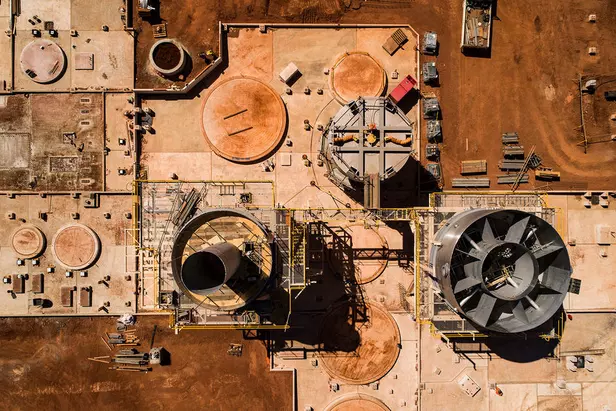

In Western Australia, the power of the sun will soon be used to extract the essential fertilizer sulfate of potassium (SOP) from the heavily mineralized Lake Way. Salt Lake Potash Limited, known as SO4, is currently commissioning the technology to produce SOP in what is a first for Australia.

Discover our water treatment technologies for the mining industry

Veolia Water Technologies offers specialized systems for the treatment of water. Our in-depth knowledge of the mining industry’s requirements enables us to offer the best technologies to customers and, through consultation, create standard and customized solutions that meet their needs for the best price.

Technologies - Mining

Mining companies face very stringent environmental regulations. We understand the unique requirements of mining operations and our worldwide expertise in mine water issues allows us to offer specialized water treatment solutions that treat water and efficiently remove a wide range of contaminants in order to help comply with discharge requirements and stringent regulations.

David Oliphant

VP Business Development - Heavy Industry

Veolia Water Technologies

Contact David through his LinkedIn account

Would you like more information about our technologies for the mining industry?

More services for our mining clients

Mining Water Treatment FAQs

What are the key elements of a mine's water management program?

There are three main elements of a mine water management program: water quantity, water quality and closure plans.

Water quantity

The quantity of water available at a mine site varies depending on the region. For example, in the western United States, water scarcity can play a role where the mine is reusing its pit water, but in parts of Canada, we are seeing the opposite where some mines have a positive water balance and have too much. Another thing to keep in mind is how climate change is going to impact the site’s water balance. This must be taken into account when determining the program. And finally, it is important to find the right balance between treatment capacity and storage needs: increased active treatment capacity reduces storage capacity and vice versa.

Water quality

What is the quality of the source water and how does the waste rock and tailings management impact the water quality? This along with the environmental regulations for effluent discharge are key in selecting the right technology for water treatment. It’s important to anticipate potential future regulations. For example, in British Columbia, Canada, regulations for selenium are becoming more and more stringent; mining companies are anticipating future regulations that may come into play in the near future, so they are already planning for these tighter regulations when developing their mine water treatment programs.

Closure plans

An often forgotten area when developing a mine water management program is to also keep in mind its closure plan. What is needed on a day-to-day basis for operations during the actual life of the mine is different from the actual post-closure operations.

How do you treat acid mine drainage?

Operating mines, as well as abandoned mine sites, generate acid mine drainage which requires water treatment to prevent adverse impacts to rivers and streams. Veolia has developed a proprietary process known as DenseSludge™ to reduce sludge management costs and improve the operating efficiency of treatment plants that have acid mine drainage.

The DenseSludge™ recycle process forms particles that settle quickly, dewater readily, and hold little water. The result is a reduction in sludge generation by nearly 90% and production of a drier sludge, which reduces the volume of water that returns to the mine pool for re-treatment. The technology has enabled mining companies to extend the life of existing sludge storage facilities and reduce requirements for building of new storage.

Why is a water treatment strategy vital for abandoned mines?

The process of dealing with — or remediating — a closed mine site can come with several key issues and challenges, especially from a water treatment perspective. At the end of their productive working lives, it is vitally important to ensure that mines are managed in a manner that mitigates or eliminates any potentially adverse effects. In practice, this means that the owners of individual abandoned or closed mine sites often have a duty of care to protect the natural environment — both in and around the area. They need to make every effort to eliminate the possibility of any negative impacts, which can include contamination of the surrounding land and surface watercourses, as well as the pollution of local groundwater supplies and drinking water aquifers.

In doing so, the deployment of an effective water treatment strategy is likely to form a key component for effective mine closure and reclamation. Contaminated water at closed mine sites can contain a range of harmful and toxic substances and dangerous chemicals, as well as metals such as cadmium, nickel, iron, copper and zinc. Such materials will tend to vary depending on the nature and location of the mine site. Furthermore, water at abandoned mine sites can be highly acidic, which can pose a dangerous threat to human, animal and plant life.

How much does a Mining Water Treatment System cost?

The cost of a mining water system is dependent on many variables such as the functionality of the mine water treatment system, the capacity of the mine water treatment system, and the performance criteria. We also require information relating to the water flow rates for your mine and the quantity of water needed to be treated. This data can be provided by a water testing laboratory and cross-regulatory requirements. If you would like a quote from Veolia Water Technologies we would need to have this vital information to start the quotation process. Please get in contact with us if you require further information.

Do the Veolia Water Technologies mine water treatment systems purify mine water?

Yes, all the different Veolia mine water treatment systems and solutions we provide will remove all water contaminants meeting all regulatory requirements and often even improve the quality of the water beyond those official benchmarks.

Can mining water be reused?

Yes, mining water can often be reused after undergoing proper treatment. Reuse applications depend on the quality of the treated water and may include industrial processes, dust suppression, irrigation, or even potable water supply. Veolia Water Technologies provides advanced treatment systems that ensure mine water meets the required standards for its intended reuse, offering sustainable solutions to reduce water wastage and enhance operational efficiency.

What is mining effluent?

Mining effluent refers to wastewater generated during mining operations, which can contain a range of pollutants, including sediments, heavy metals, sulfates, and chemicals. This effluent arises from activities such as mineral processing, dust suppression, and dewatering. To comply with environmental standards, mining effluent must be treated to remove contaminants before discharge or reuse. Veolia Water Technologies offers tailored solutions to address the specific challenges of mining effluent treatment, ensuring environmental protection and operational sustainability.

What happens to water after mining?

After mining, water used during operations typically becomes contaminated with solids, heavy metals, and chemicals, forming mine wastewater. This water is collected and treated to meet environmental regulations before discharge or reuse. Treated water can be safely returned to natural water bodies, used for site rehabilitation, or repurposed for industrial and agricultural applications. Effective mine water management is essential to minimise environmental impact and ensure compliance with regulations.

How do you neutralise acid mining water?

Neutralising acid mining water involves processes to raise its pH and remove dissolved metals. Common methods include adding alkaline substances such as lime, limestone, or sodium hydroxide, which neutralise acidity and precipitate heavy metals as solids. Advanced solutions, like those offered by Veolia Water Technologies, may also include biological treatment, membrane filtration, or ion exchange to further improve water quality and meet strict regulatory standards.