To separate colloidal suspensions and oily emulsions under satisfactory speed conditions (for example under the influence of weight in the sedimentation or clariflocculation step or under dissolved air influence in the flotation), it is necessary to respectively unify the colloids to form bigger particles and to break the emulsions.

Overview

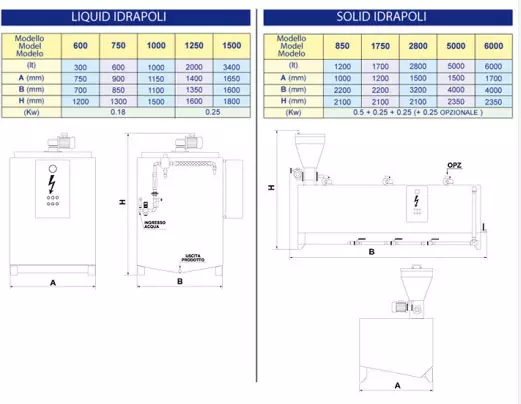

In fact, the sedimentation, clariflocculation as well as flocculation take place only after the destabilization of colloidal particles, i.e. through the cancellation of the superficial charges which determine the repulsion preventing aggregation. To have this effect, proper electrolytes chemical compounds which form hydrolysable metal ions or ionisable organic polymers (polyelectrolyte) must be added to the waste water. To obtain an excellent coagulation and flocculation, necessary to reach a high sedimentation, clariflocculation and flotation efficiency, Idracos designed LIQUID IDRAPOLI™ and SOLID IDRAPOLI™ - proper automatic unit for preparation and dosing of coagulants and flocculants.

APPLICATIONS

The LIQUID IDRAPOLI™ and SOLID IDRAPOLI™ units were designed and built especially for wastewater treatment plants.

They are usually installed before settling tanks, clariflocculators and flotators.

Another very important application is in sludge treatment where they are installed to service centrifugal separators, belt presses and filter presses.

Applications

HOW THEY WORK

LIQUID IDRAPOLI™ was designed and built to prepare liquid polyelectrolyte solutions with water having variable concentration according to their use. Liquid polyelectrolyte will be taken from the container and dosed by a screw pump equipped with hydraulic variable speed inside the injector where the first mixing with fresh water takes place.

Subsequently the solution passes through static mixer where it is additionally mixed to a stainless steel tank provided with a blade stirrer which accomplishes the mixing and product maturing. A set of probes installed in the tank determine the start and stop of the equipment according to chemicals consumption and another probe signals emergency in case of chemicals lack.

LIQUID IDRAPOLI™ is built entirely in AISI 304 stainless steel with two bottom discharges, overflow and automatisms installed at water inlet.

SOLID IDRAPOLI was designed and built to obtain a suitable quantity of polyelectrolyte powder in liquid solution having the concentration which varies according to the application. Water comes into the first tank through a system of automatisms and flow-meter. The polyelectrolyte is loaded in proper hopper and fed into the first tank by means of variable speed conveyor. An agitator starts the dissolution step. The solution will be transferred by means of a siphon into the second tank equipped with agitator. From here the solution will be transferred through the siphon to the third tank where it is possible to select variable agitation with pause/operation and holding times.

A set of probes controls the process cycle.

Model; V= Volume; A= Width; B= Length; H= Height; P= Installed electric power