The Opaline™ solution : The sanitary safety for drinking water

Overview

Developed by Veolia Water Technologies for drinking water production, Opaline™ combines membrane technologies and activated carbon adsorption in order to remove:

- pesticides,

- Total Organic Carbon (TOC)

- endocrine disruptors

- micro-organisms,

- turbidity,

- taste and odours.

Features and Benefits

Opaline™ :

- improves drinking water quality, with regards to safety, organoleptic parameters (taste, odours) and other factors (colour, ...),

- guarantees a high quality potable water,

- constitutes a reliable and safe solution,

- reduces construction costs through a compact design.

Quality of the produced water:

- Turbidity < 0,2 NTU

- Pesticides < 0,1 µg/l

- Parasites: 5 log removal

- Bacteria: 5 log removal

Applications

Opaline™ is particularly well adapted for the treatment of :

- Ground waters (including karstic waters) contaminated with pesticides and micro-organisms

- Surface waters with low turbidity, contaminated by micro pollutants and micro-organisms, or as polishing.

References

Opaline™, as the ultimate solution to secure drinking water production, is already used in 24 plants around the world.

|

Flow (m3/d) |

Commissioning

|

|

|---|---|---|

|

Parker, CO-USA (Kruger Inc.) |

37 850 |

2011 |

|

Lucien Grand (OTV France) |

60 000 |

2009 |

|

L'Hay-les Roses (OTV France) |

150 000 |

2008 |

|

Nancy (OTV France) |

90 000 |

2007 |

|

Annet-sur-Marne (OTV France) |

3 600 |

2002 |

|

Windhoeck (Namibia) |

21 000 |

2001 |

|

North Mymms (United Kingdom) |

36 000 |

1999 |

|

Clay Lane (United Kingdom) |

160 000 |

1998 |

|

Ocana (OTV France) |

300 |

1996 |

Applications

Operating Conditions

Opaline™ can be implemented in two different ways :

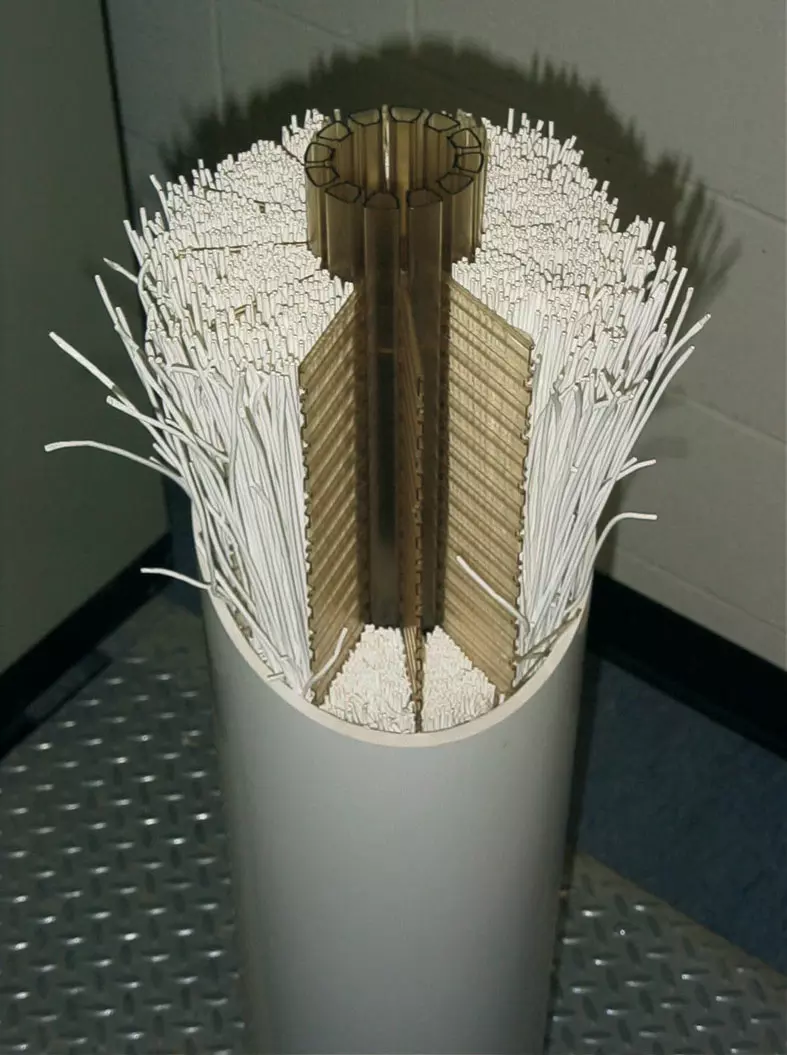

- Opaline™ S :

Sequential water treatment whereby the activated carbon stage is separate from the membrane filtration stage. Either GAC or PAC activated carbon can be used. - Opaline™ C :

The activated carbon stage is combined with immersed membrane filtration. Powdered Activated Carbon (PAC) is used in this case.