A revolutionary waste to energy technological solution transforming palm oil manufacturing processes, responding to mounting environmental concerns while generating value for producers.

Overview

Affordable and Efficient Pome Treatment

Palm oil has become a major, global agricultural commodity, used for food and non-food applications and most recently touted as a promising feedstock for biofuel production.

In coping with the burgeoning water challenges and rising demand, the palm oil mills are relying on technology for a better resources management and water conservation.

POMETHANE® is an anaerobic thermophilic digestion process which maximizes the yield of biogas production and offers an attractive solution for the treatment of high concentrated and hot water streams.

This new technology treats efficiently palm oil mills effluents (POME) thanks to an optimized process design that operates at higher loading rates compared to conventional mesophilic digester or lagoon system.

The technology's economic viability, the dramatic reduction in environmental impacts and the ability to create value hold out the potential to revolutionize industry practices.

POMETHANE® provides an immediate opportunity to improve the palm oil industry environmental performance toward a responsible model of sustainable production.

Through POMETHANE®, we help you to meet your operational, economic and environmental challenges.

Features and Benefits

Pomethane® constitutes a best practice' application for the management of industrial waste in the palm oil sector.

Technology Features

- No cooling requirement before treatment

- Operation of the plant at a temperature of 52-55°C

- Highest biogas yield

- Significantly shorter retention time

- Compact design & small footprint

- Safe & reliable process design

Renewable Energy Production

The process captures the methane from the waste organic matter to run a gas engine to generate electricity. An alternative option is to burn the biogas in a boiler to generate steam and hot water.

- Use the energy produced with the biogas plant for your mill production and staff quarters

- Generate revenue through the sale of excess electricity back to the grid

Environmental Pollution Minimization

Pomethane® is specially designed to reduce the impact of your activities since the energy is produced from a renewable source and producing biogas as an energy source is Co2 neutral.

The combination of Pomethane® with a tertiary treatment step opens up additional value creation potential through the reuse of water for irrigation and the application of surplus biomass as fertilizer.

Applications

Treatment Process

POME is generated mainly from oil extraction, washing and cleaning processes in the mill and cannot be discharged prior to specific treatment due to its acidic nature and very high biochemical oxygen demand (BOD).

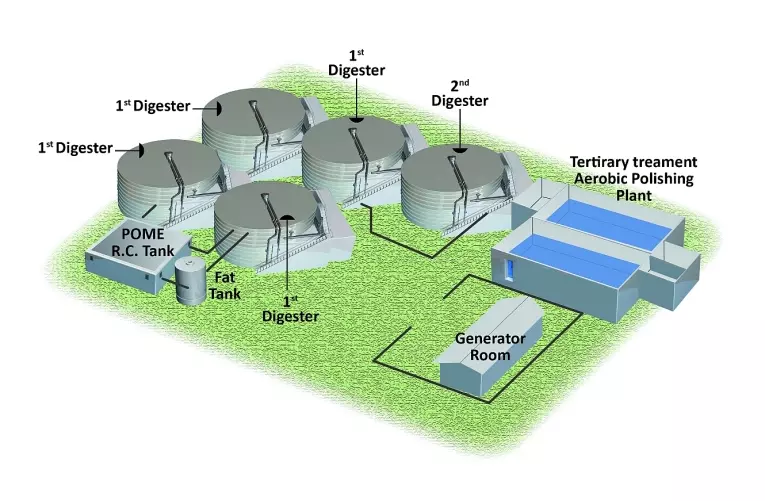

The POME is treated in thermophilic operated first stage digesters (digestion temperature 52˚C), which will assure optimal digestion of the POME at HIGH loading rates and SHORT retention times. A secondary stage digester is designed to assure full degradation of the organic matter and maximize the biogas yield.

Benefits

- Technical solution that meets Clean Development Mechanism requirements

- Economic efficiency

- In compliance with international environmental standards

- Environmentally friendly

- Renewable energy product

Advantages

Anaerobic digestion of POME by use of thermophilic bacteria provides a number of advantages compared to the conventional mesophilic bacteria:

- The retention time is significantly shorter at thermophilic operating conditions which results in a reduction of the digester tank size and thus capital cost and maintenance.

- Thermophilic bacteria are capable of digesting more complex degradable substances, which may not be degraded by mesophilic bacteria. This will result in an increase of the biogas yield.

- At mesophilic temperature range fungi and vira may grow in the substrate thus causing potential health hazards from the effluent. Unwanted microbiology will not survive in the thermophilic temperature range.

The biogas from the digesters is collected and treated before usage in the gas utilisation (gas engine or boiler) system.

The effluent from the secondary digester will run through a clarifier system. The effluent from the clarifier will be treated in the downstream wastewater treatment system.

A part of the sludge will be recycled to the digester and the excess sludge can be composted after further decanting or taken straight to the plantation as fertilizer.

Enhanced performance

- COD removal exceeding 90%

- Final effluent discharge of BOD < 20ppm

Optimum Payback

Depending on capacity and COD/BOD content, revenue can be generated through the generation of electricity and fertilizer.

For example, with Pomethane® a 60-ton plant could produce:

- 64 GWh/year ~ 7.3 MW of gas energy (at 9.94 kWh / m3 CH4), sufficient to generate 2.9 MW of electricity (at 40% efficiency),

- 320,000 tons of degassed biomass annually, separated by decanter, yielding a liquid fraction of 272,000 m3 and fiber fraction of 48,000 tons, convertible into 20,000 tons of compost.