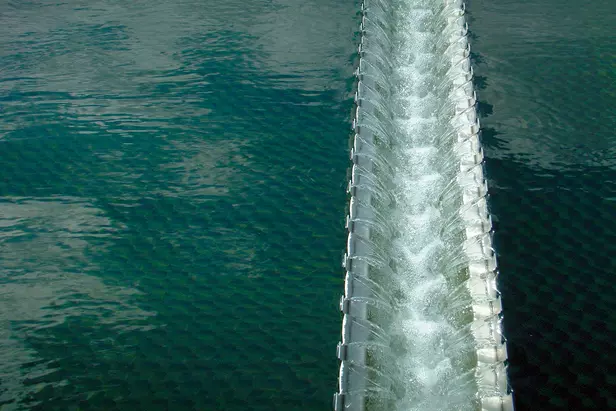

A range of products offering a high-rate and compact water clarification process for the production of drinking water, process water and the treatment and reuse of wastewater.

Overview

Water clarification is a fundamental step in water treatment to remove suspended solids from water and in wastewater treatment.

Offering high-rate clarification, Actiflo is a family of products designed specifically for compact water and wastewater clarification processes.

For the production of drinking water and process water, Actiflo treats surface water, groundwater, seawater and brackish water. This ability is vital as drinking water treatment plants adapt to the impacts of climate change such as storm events and the growing importance of alternative raw water sources.

To ensure water standards are maintained, Actiflo increases the settling speed compared to conventional settling and allows treating a flow rate up to 10 times higher than the sludge bed process.

It is particularly effective in eliminating turbidity, natural organic matter, color and algae. For the specific needs of industry, Actiflo is also suitable for the treatment of cooling tower make-up water and boiler feed pretreatment.

For municipal and industrial wastewater, Actiflo can be implemented at all stages of the treatment of municipal effluents, including primary and secondary clarification, tertiary polishing and wastewater reuse.

How does Actiflo work?

Actiflo is a high-rate water clarification system based on Veolia’s patented ballasted flocculation process. It enhances flocculation using microsand and polymers to increase the weight of flocs, allowing for significantly faster settling of up to 40 to 100 times faster than conventional clarification methods. This technology is essential to the production of potable water (or drinking water), enabling the rapid delivery of high quality water to meet growing demand.

Suitable for both municipal and industrial applications, Actiflo effectively removes toxins, organic matter, heavy metals, ash, and coal fines. It ensures safe and compliant water across a range of industries, including pharmaceuticals, food and beverage, power, mining, and chemicals.

Actiflo has been exclusively developed and patented by Veolia Water Technologies and has been in use for over 30 years. There are more than 1,100 Actiflo references all over the world featuring more than 1,800 units, including more than 900 package plants, in municipal and industrial water and wastewater applications.

Features and Benefits

Fast and flexible: A compact water and wastewater treatment solution ideal for diverse applications in both municipal and industrial sectors.

High-Performance: Removes turbidity and suspended solids (TSS) by up to 99%, treating all types of water and wastewater.

Safe and Efficient: Effectively neutralises harmful toxins to secure drinking water production.

Rapid Deployment: Achieves optimal treatment performance in just minutes.

Robust and Adaptable: Handles fluctuations in water flow and contaminant load with ease.

Customisable: Wide range of options to enhance system monitoring and efficiency.

Cost-Effective: Its small footprint reduces construction needs and water usage, supporting sustainable wastewater management.

Applications

Services

Veolia offers full lifecycle support including factory acceptance testing, installation, and logistics. Additional services include:

Product range and Resources

Contact

The principle of ballasted clarification has been known and used since the 1960s. The latest generation of high-speed clarifier based on this process is the Actiflo which combines the advantages of ballasted floc with those of lamellar decantation. The technology has become an essential tool in clarification with an inert chemical element that still offers continuous sludge discharge, safety and adaptability to incoming load variations.

Philippe Sauvignet

Industrialization Manager

Contact Philippe through his LinkedIn account

FAQ about Actiflo®

How does clarification in water treatment using microsand work?

Microsand-enhanced ballasted flocculation works by attaching fine sand particles to flocs through a polymer bridge. This increases the flocs' weight and improves settling speed while accelerating the reaction time. The result is efficient solid removal of over 90% within a 15-minute process window.

What are the benefits of microsand-enhanced clarification?

Actiflo delivers reliable, high-quality clarified water even under variable influent conditions. Its resilience to turbidity spikes and seasonal changes makes it ideal for treatment facilities requiring operational stability.

What is ballasted flocculation?

Ballasted flocculation is a fast-settling separation process used in treating drinking water, stormwater, and wastewater. It incorporates a ballasting agent (microsand) and polymers to enhance floc formation and improve sedimentation.

How does Actiflo contribute to sustainable wastewater management?

Actiflo supports sustainable wastewater management by enabling high-efficiency treatment in a compact water system. Its rapid processing and low chemical usage reduce resource consumption and operational costs. With the ability to treat complex industrial and municipal wastewaters for reuse, Actiflo promotes circular water strategies and environmental stewardship.

Case Studies

With an increased water demand due to population growth, coupled with the existing plant facing more stringent requirements and nearing its capacity, the City of Red Deer was planning a costly plant expansion. An additional clarifier and UV disinfection system was proposed to be installed in an expansion to the existing facility. An alternative solution was desperately needed. Actiflo was tested and selected due to its small footprint and performance at removing organic carbon. This was the only process that allowed a complete retrofit inside one of two existing contact clarifiers, while increasing the plant capacity by 80% (120,000 m3/d). And so a costly plant expansion was avoided. Since this date, Actiflo has also successfully managed storm events and flooding where Red River's flow rate went from a normal 150 cubic metre per second (cu.m/s) to 18,000 cu.m/s. These record turbidites were caused by river banks being literally washed away. However, Red Deer's drinking water quality remained unaffected.

The client needed to manage stormwater runoff from a 37-acre coal storage yard utilized as a part of daily operations at an industrial site in Southwestern Pennsylvania following new NPDES permit discharge limitations for total suspended solids, iron and manganese. Actiflo provided the solution by utilizing sand-ballasted to treat water with changing flow rates within a small footprint, typically less than 10% of the area required for conventional settling technology. We combined the high-rate settling process with pH adjustment and chemical pretreatment to precipitate the metals of concern and produce an effluent of consistent, compliant quality.