A compact process, low in energy and chemical reagents that leaves no trace of carbon in the sludge.

Overview

Our patented innovation, Opacarb FL, was introduced to the market in December 2020. It is a compact, environmentally friendly treatment process that uses energy sustainably and does not need chemicals, while also producing no sludge and minimizing water loss throughout its entire operation.

It consists of passing the drinking water or wastewater to be treated through a reactor containing the bed of granular activated carbon in an ascending flow. This process also makes it possible to renew the activated carbon bed without having to stop the reactor, guaranteeing a permanent level of treatment efficiency.

How does the Opacarb FL process work?

The treatment of micropollutants with Opacarb FL takes place upstream through a filtration process for drinking water or at the end of the treatment line for municipal and industrial wastewater treatment plant processes. It can also be combined with a short ozonation process enabling the degradation of micropollutants by oxidation. Care is taken to limit the duration of contact between the water and ozone to avoid the development of harmful by-products.

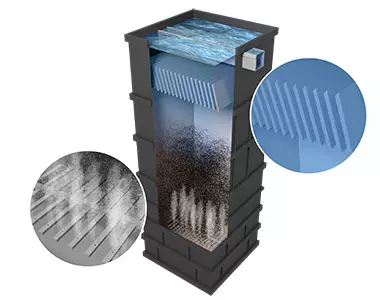

Opacarb FL traps micropollutants in a micro-granular activated carbon fluidized bed reactor. The water to be treated enters the foot of the fluidized bed reactor via a diffusion ramp which ensures optimal distribution of the water flow through the activated carbon.

With the water flow maintained at a speed, it allows for the activated carbon to move in suspension. By using carbon with appropriate granulometry, higher speeds of 20 to 40 meters per hour can be achieved, which reduces space requirements for the process.

This significantly reduces the surface area of the reactor, while maintaining a high contact time and ensuring suspended solids are not trapped in the carbon bed, avoiding the need for cleaning.

Once treated, the water is collected in the upper part of the structure through the gutters or launders.

Applications

In drinking water treatment plants the use of micro-granular activated carbon allows for the treatment of metabolites and pesticides.

At the outlet of wastewater treatment plants, during refining treatment, it limits the release of micropollutants into the environment strictly adhering to regulations in place.

Features and benefits

What are the advantages of Opacarb FL?

Offering several advantages over other granular activated carbon technologies, Opacarb FL has a high efficiency at drinking and wastewater treatment plants and is capable of reducing up to 99% of micropollutants and their ozonation by-products to produce high-quality water.

The performance of the technology is based on the regular supply of new micro-granular activated carbon to maintain an active filter mat. The carbon is regularly extracted, drained and then sent to a thermal reactivation unit for reuse which is a huge advantage compared to PAC (powder activated carbon).

Other advantages include:

- Continuous granular activated carbon dosing

- Compact and modular

- Simple to operate

- Suitable for installations of all sizes

- Low energy consumption

- No activated carbon sludge

- No use of coagulant, flocculant or polymer chemicals

Applications

Services

Contact

Acting against micropollutants is a priority shared by all of our teams, researchers and experts. The solutions we develop aim to anticipate future standards for the treatment of micropollutants. Granular activated carbons have made it possible to develop technologies with very high environmental performance, low in energy and reagents, and these technologies are already implemented in drinking water plants.

Christophe Sabourdy

Drinking water expert, Technical Department

FAQ about Opacarb™ FL

Why is granular activated carbon good for drinking water treatment?

Granular activated carbon is highly effective in drinking water due to its large surface area and porous structure. It efficiently adsorbs a wide range of contaminants, including organic matter and inorganic micropollutants, improving and helping to produce high-quality water by removing impurities, odors and taste compounds. Granular activated carbon is versatile, cost-effective, and can be regenerated, making it a good choice for enhancing water safety.

Why is granular activated carbon good for wastewater treatment?

Granular activated carbon is widely used in wastewater treatment owing to its adsorption capacity, versatile treatment of a wide range of contaminants and effective chemical reactivity with pollutants. The microporous structure and large surface area of granular activated carbon provide numerous active sites for adsorption, making it proficient in trapping organic matter and inorganic pollutants. Also, its capability to address diverse water quality issues further contributes to the widespread use of granular activated carbon in wastewater treatment.