Struvia technology has been developed by Veolia Water Technologies to facilitate the recovery, the valorisation and the reuse of phosphorus contained in wastewater and in concentrated industrial water.

Overview

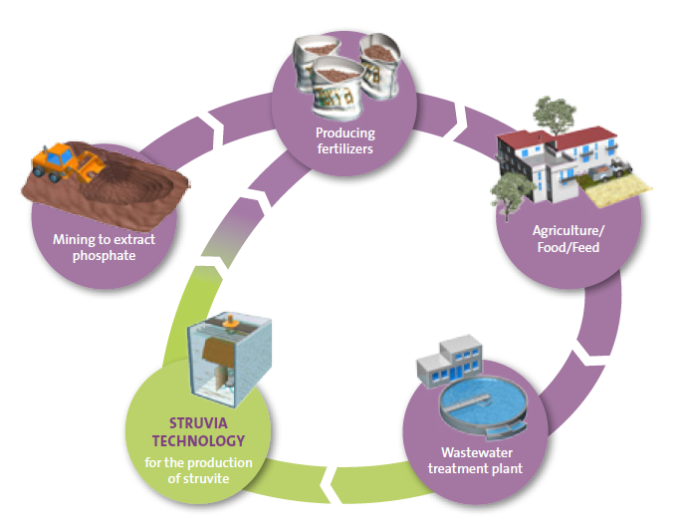

Phosphorus is a key ingredient in the fertilizers used in agriculture and for animal feed. It is primarily produced by mining, and no synthetic substitute currently exists.

Struvia allows for recovery of phosphorus from effluents produced by industrial, agricultural and municipal activities, as struvite crystals (mineral substance composed with magnesium ammonium phosphate; also called MAP) . This opens the way to a local reuse of phosphorus, especially in agriculture.

The recovery of phosphorus is especially important considering declining phosphorus rock reserve. It limits the release of phosphorus into the natural habitat, which causes euthrophication (an imbalance in an aquatic environment).

The Struvia process is adapted to circular economy and sustainable development projects.

APPLICATIONS

Struvia is the ideal solution to allow industries and municipalities to turn a cost (purchase of metal salts, sludge disposal and maintenance caused by uncontrolled struvite precipitation...) into a benefit (sale of struvite as a fertilizer).

Municipal applications

- Wastewater treatment plants equipped with anaerobic digesteurs

- WWTP equipped with biological dephosphatation whishing to install sludge anaerobic digestion

- WWTP equipped with anaerobic digestion wishing to install biological phosphorus treatment

- Household waste methanization plants

- Territorial methanization sites

Industrial applications

- Agriculture: livestock effluent treatment

- Food & beverage industries: distilleries, dairies, breweries, slaughterhouses, potato processing, where fermentation effluents are treated to be reclamed

- Agrochemicals: fertilizers and biofuels production

Struvia solution key benefits:

- Recovering phosphorus contained in wastewater leading to:

- A reduction in the production of sludge

- the production of sludge with a reduced phosphorus content

- Reduced operating costs for existing facilities :

- No more clog pipes, preventing dysfunctions and unplanned operation downtime caused by uncontrolled struvite precipitation that clogs pipes

- Reduction of the reactive products injection into the wastewater treatment process

- Limited space requirements

- Reduced maintenance

- Low investment and operating costs (combined with sales of struvite produced)

Applications

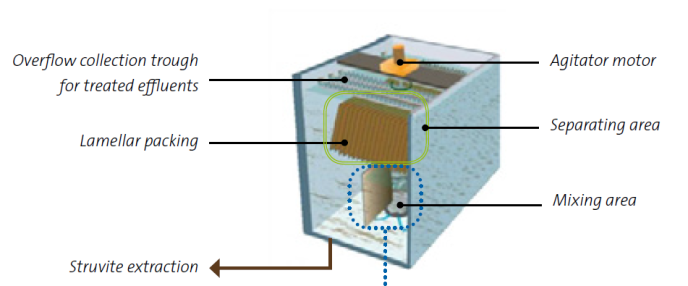

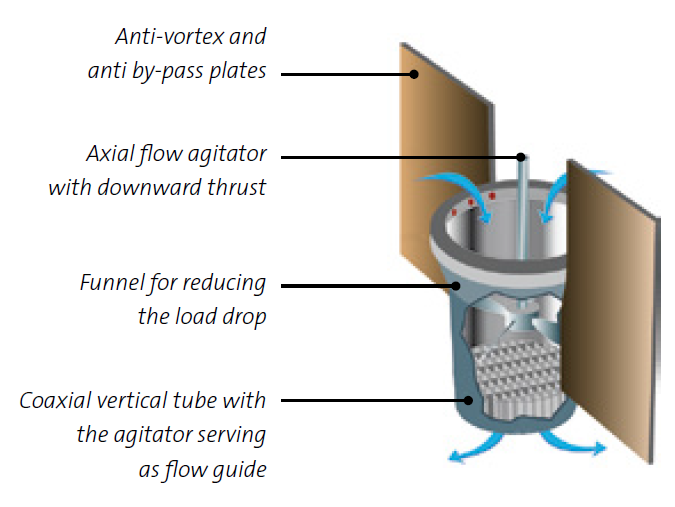

Effluent containing high concentrations of phosphorus are fed to a continuous stirred tank reactor where rapid mixing is achieved by using a special mixing system : Turbomix.

Struvite precipitation is initiated by increasing the pH and by addition of a magnesium salt.

An integrated lamella settler ensures the separation of the treated effluent and the produced struvite prills. These are pumped and directed to a draining and storage facility before they are sent to the packaging unit.

Turbomix is patented by Veolia Water Technologies. It encourages crystallization and growth of Struvite pellets.

Draining then drying the struvite produced using a filter bag at Braunschweig WWTP